When iTUB was launched back in 2010, a decision was made to only invest in polyethylene PE plastic tubs from Sæplast which are 100% recyclable. These PE tubs are triple-layered which makes them both durable and robust. The Closed Cell Core design of the tubs is unique because it does not absorb liquid if the outer core gets punctured or damaged. This optimizes the hygiene control for the tub.

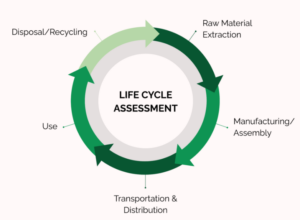

Because of strength, the tubs are expected to last for up to 15 years in closed circular system. Once they are deemed not safe to use, or within our replacement plan, they are shredded and made into new tubs. This reduces plastic waste and limits the use of new virgin material when constructing a new tub. The use of recycled plastic produces less carbon emission.

Generally, there are two types of insulated plastic tubs in the market; PE (polyethelyne) and PUR (polyurethane);

PE TUBS

PE insulated tubs are manufactured from and insulated with polyethylene (PE) which is 100% recyclable. The PE plastic is triple-layered, making this the strongest tub in the market. The PE tub is made of one material throughout. Because of this, both the outer shell and the insulation are made from the same material. This means that the container is recyclable. They have a smooth surface which is easy to clean and drain. The Closed Core Cell design does not absorb liquid which optimizes hygiene control.

- Manufactured from and insulated with polyethylene (PE) plastic

- 100% recyclable (because of polyethylene insulation)

- Triple-layered, making this the strongest insulated tub in the market

- One-piece seamless triple wall design which improves hygiene

- Closed Cell Core design does not absorb liquid, if the outer core gets damaged/punctured

- Smooth surface which makes it easy to clean

- Does not add weight over time

PUR TUBS

PUR refers to the polyurethane (PUR) insulation that is injected into the walls of the tub, ensuing a high insulation value. The tubs are seamless rotomoulded double-walled. The primary purpose of PUR is tubs is the temperature retention. PUR tubs have less strength compared to PE constructed tubs. If the outer core of the PUR tubs gets damaged, water can flow into the insulation area. This means that PUR tubs can add weight over time. PUR tubs are not recyclable.

- Manufactured from polyethylene (PE) and insulated with polyurethane (PUR)

- Not recyclable (because of polyurethane insulation)

- Double-walled design, less strength

- High insulation factor

- Weight changes over time if outer core gets damaged