iTUB Rental always ensure their stock of 50,000 tubs are in the best condition possible. In a normal year, they repair around 20 percent of their stock.

– iTUB has established repair services in Iceland, Norway, and the United Kingdom. In a normal year, we repair around 20 percent of our stock. We strive to keep the tubs in good condition minimizing the waste from damaged tubs. Still, and more importantly, we strive to maintain the standards for safety, both for the user and the contents, says managing director Hilmir Svavarsson in iTUB Rental.

iTUB and PPS

In the United Kingdom, iTUB has joined forces with PPS Midland Ltd as their repair service partner.

– PPS collects iTUB bins from end-users around Lincolnshire, England, and wash them on a weekly basis. If any of our tubs are damaged, PPS repairs them onsite in Grimsby, says Svavarsson.

Reduces waste

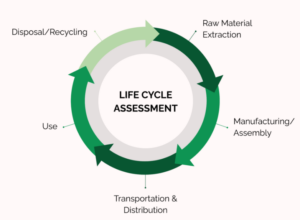

Currently, PPS repairs on average 75 iTUB bins a week. This amounts to 3,900 bins repaired in an entire year that would otherwise be condemned to waste. The repair service reduces waste and supports the circular economy.

– PPS specialist technicians inspect each container to make sure any damaged equipment is repaired to the standard set by iTUB, says Steve Nicholson, Operations Director at PPS.

Added value

While reusable packaging provides environmental benefits compared to single-use packaging, even the most robust plastic transit packaging can get damaged after years of use. The PPS repair service offers an added value that keeps waste to a minimum. It´s also a more cost-effective service than buying new bins when they are damaged.

– In working environments, especially in demanding environments like those that iTUB experiences, damages will always occur. The most common damages are punctures in the bin from forklift trucks and broken runners, says Nicholson.

Food safety and user security

A damaged tub is not only a challenge to tub hygiene. It can also reduce the security of the users handling the tubs.

– When tubs are damaged in action, they may become less secure for stacking and therefore a risk to the user. Puncture in the tub can also lead to hygiene being more difficult to maintain. Consequently, our tubs must be checked and repaired accordingly. Safety is at the forefront at iTUB, and we strive to keep the tubs in as good condition as possible, says managing director Hilmir Svavarsson at iTUB Rental.

Ready to be put back in circulation

When the experienced technicians at PPS finish their work on the damaged tubs, the tubs are ready to be put in circulation again after being re-washed:

- The first step is to prepare the area of the bin that needs attention

- The damage is then filled in with hot weld via a plastic welding gun

- Finishing with a smooth surface on the inside and outside by using a smooth electric sander

- Once repaired, the bins are washed and ready to go back into circulation

Good for the economy

For companies interested in the circular economy, the benefits are two-fold; a waste reduction is good for the environment, and the cost of repairs often amounts to less than 10 percent of the cost of purchasing a new tub.

– It makes the industry more sustainable, and it’s good for customer’s bottom line too, says Nicholson.

Significant growth

He believes the circle economy will grow significantly in the years to come. With the Green Shift, environmental business models have many benefits.

– Consumers are becoming more aware of their environmental footprint and the carbon footprint of the businesses they use. Government policy is influencing this behavior further. As a result of this, reusable packaging continues to go from strength to strength, says Nicholson.

Future model

The iTUB staff placed in Iceland, Norway, and Denmark believe renting tubs can reduce the carbon footprint from the North Atlantic seafood industries.

– The tub rental is just a small part of the value chain, but our service offers an important contribution to the green shift. We believe reusing and sharing recycled tubs is the future model for seafood transportation, Svavarsson ends.