New tubs made with renewable energy

Our commercial fishing tubs are crafted at Saeplast’s facility in Dalvik, Iceland, marking a pivotal advancement in sustainable manufacturing. Saeplast has revolutionized the industry by

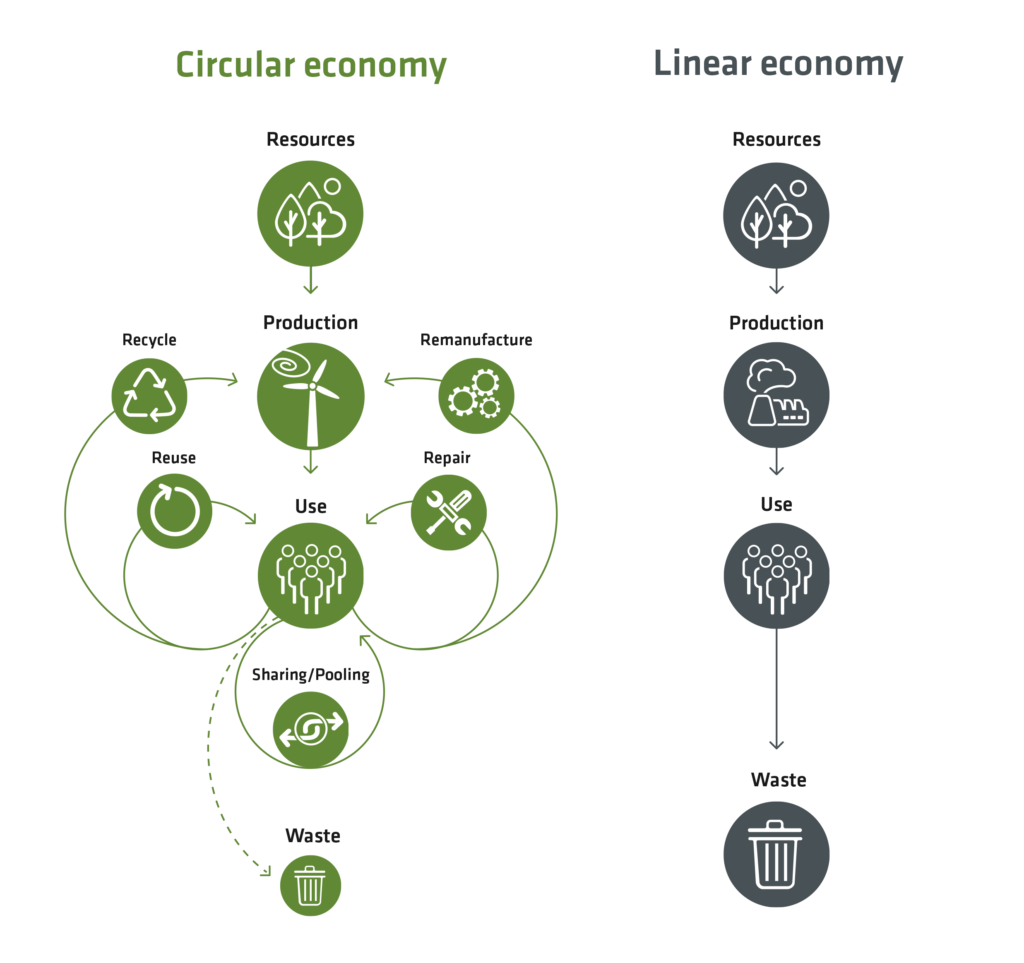

The circular economy is a system aimed at eliminating waste and improve the continual use of resources. In iTUB, we offer a pool of tubs for users to share. We take good care of our tubs to make sure that they last as long as possible. When our tubs are worn out, we grind up the plastic and use it as a raw material in the production of new tubs. This is how we reduce the environmental impact of our business, and contribute to reduce the environmental impact of the seafood industry in Europe.

Over the last decade, countless businesses across the globe have emerged their business through sharing their under-utilized assets. The sharing economy is based on a belief that sharing assets will increase the utilization, and reduce the need to produce new assets, held by individual businesses.

Sustainability matters!

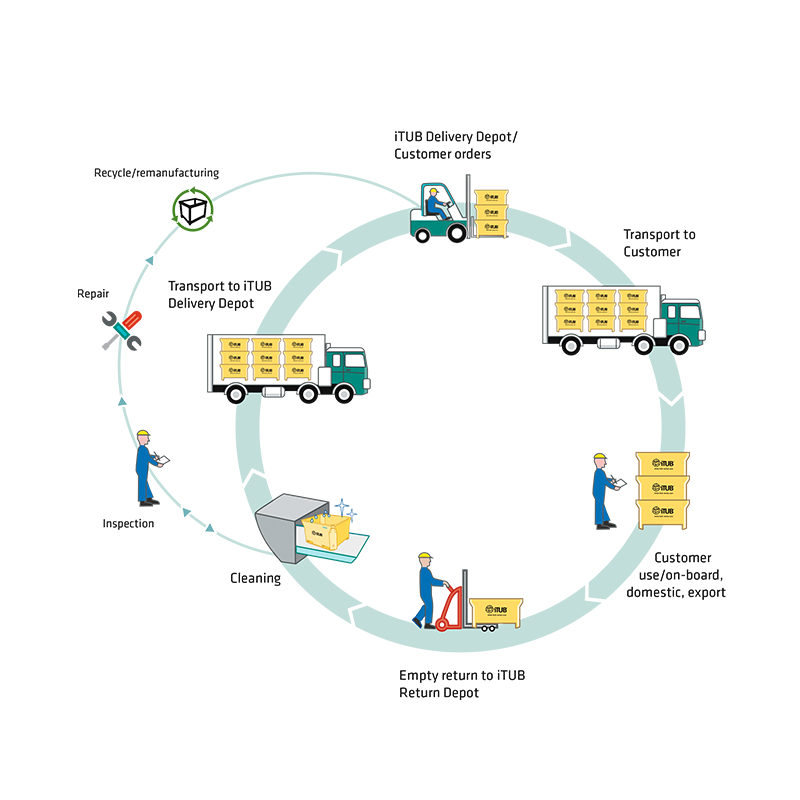

By using our equipment several times over many years in an effective logistics system, we lower the impact that the equipment has on the environment through decreased carbon footprint. Our equipment has lower carbon footprint than any single use equipment available.

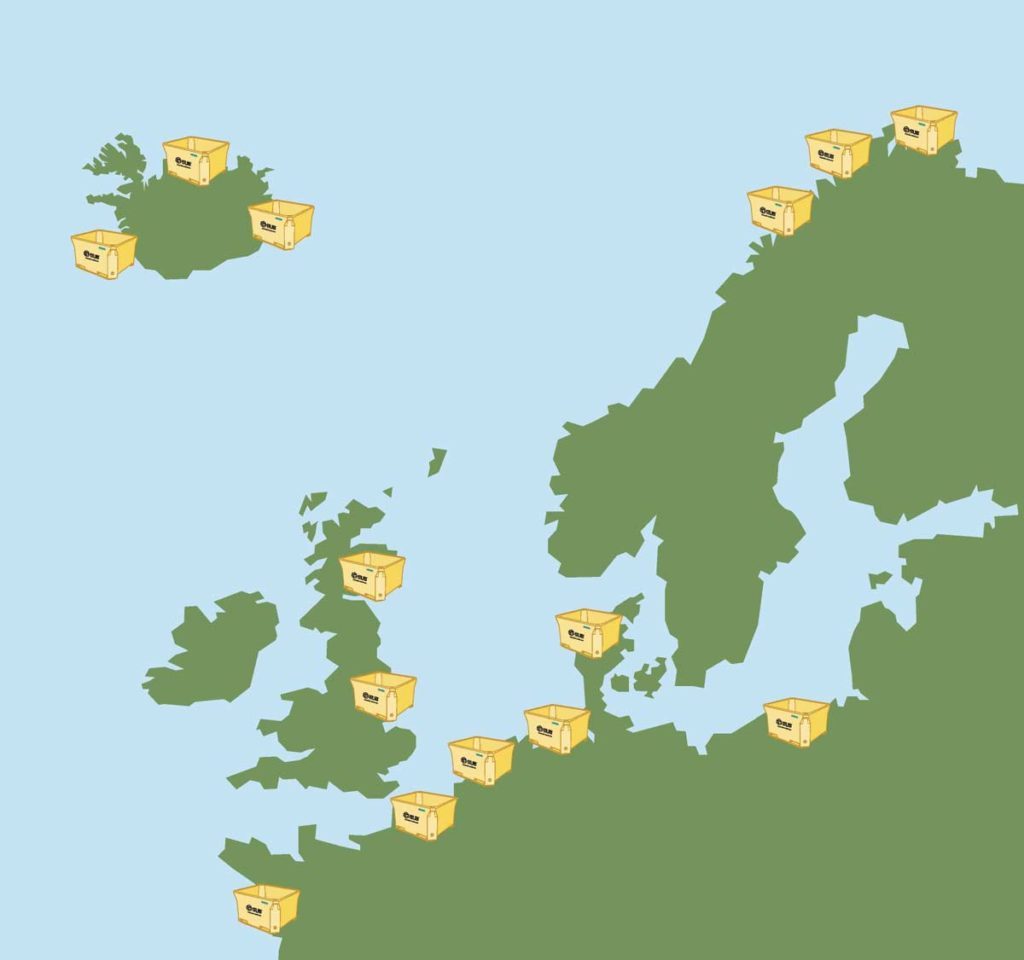

iTUB believe that sharing tubs is better for the environment and the economy, than tubs held individually by companies in the seafood industry. That’s why our founders decided to establish a pool of tubs, with an effective system of distribution across Europe, that we rent to the seafood industry.

In order to keep our equipment in the best possible condition at all times, we systematically repair all damages at our quality control points throughout our effective logistics network. Effective repairing strategy will also make sure that our tubs last as long as possible to further decrease their carbon footprint.

All our equipment is made from Polyethylene that is 100% recyclable. We make sure that once our tubs have ended their service, they are sent through our recycling process, where they are milled to PE particles and processed to recyclable PE granules. The fact that our equipment is made from PE material througout, including the insulation, they are easily recyclable.

The recycling process has been developed in a way so that the recycled granules can be used to produce new tubs. With our partners, we have developed a process to manufacture new tubs out of the recycled granules from older tubs. This is our commitment to close the loop in terms of sustainable equipment for the industry.

Our commercial fishing tubs are crafted at Saeplast’s facility in Dalvik, Iceland, marking a pivotal advancement in sustainable manufacturing. Saeplast has revolutionized the industry by

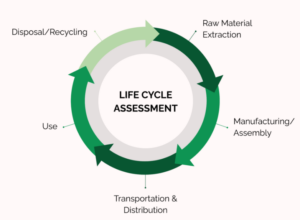

We’re thrilled to share that iTUB has contributed to groundbreaking academic research, highlighting our commitment to sustainability. This Life Cycle Assessment (LCA) study reveals that

In a quaint coastal town nestled amidst the breathtaking landscapes of Dalvik, Iceland, lies the heart of a remarkable endeavor – Saeplast. This unassuming company

Quicklinks

Links of interest