Our commercial fishing tubs are crafted at Saeplast’s facility in Dalvik, Iceland, marking a pivotal advancement in sustainable manufacturing. Saeplast has revolutionized the industry by transitioning from oil-based to renewable energy sources for rotomolding tubs. This transformation makes it the world’s inaugural rotomoulding enterprise to operate exclusively on electrical power, substantially cutting CO2 emissions. Given the high energy demands of the production process, this shift is particularly impactful. Celebrating 40 years of operation, Saeplast Dalvik-based plant operates on Iceland’s renewable energy, which constitutes 100% of the country’s electricity production—approximately 73% from hydropower and 27% from geothermal sources.

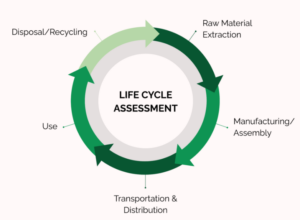

This evolution from traditional energy sources to renewables is a cornerstone of our commitment to the circular economy. By aligning our manufacturing processes with principles that prioritize sustainability and resource efficiency, iTUB is not just renting fishing tubs; we’re nurturing a cycle of continuous use and reuse that minimizes waste and environmental impact. Here’s how this commitment manifests in tangible benefits:

– Enhanced Sustainability: By harnessing the power of Iceland’s renewable energy, we’re ensuring that our process is sustainable for the long haul. This approach lessens our dependency on finite resources and aligns with global efforts to combat environmental degradation and climate change.

– Reduced Carbon Footprint: The transition to renewable energy sources significantly slashes the carbon footprint of our tub production. Iceland’s abundant geothermal and hydroelectric resources provide an ideal backdrop for manufacturing that respects the earth.

– Operational Efficiency and Cost Savings: The efficiency of Iceland’s renewable energy not only reduces operational costs but also allows us to reinvest savings into further sustainable practices or pass them onto our customers. This efficiency is a boon for the circular economy, enabling a cycle of continuous improvement and innovation.

– Commitment to Environmental Preservation: Our use of renewable energy is a pledge to preserve the natural world. It aligns with broader objectives like pollution reduction, conservation of resources, and protection of ecosystems. In a nation renowned for its natural beauty, such as Iceland, this commitment is particularly resonant.

Saeplast’s move to renewable energy is a reflection of iTUB’s dedication to the circular economy. By producing our commercial fishing tubs with renewable energy, we’re not just making a product; we’re contributing to a sustainable future where every item is part of a larger, regenerative cycle. This philosophy underpins everything we do, ensuring that our actions today foster a healthier planet for generations to come.