Our mission to become a net-zero emission company is an ambitious goal that requires a comprehensive strategy and commitment to sustainability. Here are several ways we have worked toward achieving net-zero emissions.

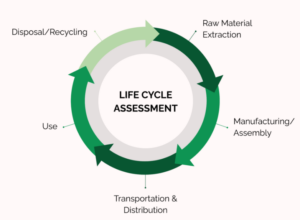

- Our operation is based entirely on the circular model, not linear. Our resources are recycled back into our business which results in zero waste where nothing gets thrown away. By creating a circular economy around our business, we lower our carbon emissions.

- All new tubs are made with 100% geothermal energy. With the installation of the world´s largest casting furnace, at Sæplast plant in Dalvik Iceland, it is now possible to produce all new tubs with renewable energy instead of fossil fuel. This reduces greenhouse gases (GHG) by at least 50%.

- Our tubs are made from strong and durable PE plastic which is fully recyclable. On average, the tubs last between 12 and 15 years. To uphold safety and prolong durability, the tubs are fixed when needed. To extend durability, tubs are repaired. About 20% of tubs are repaired annually. In the circular economy, we want the goods and materials to stay in circulation for as long as possible. In fact, reuse and repair are the building blocks of the circular economy. This can contribute to climate change mitigation by preventing resource depletion and diverting products and materials from landfills.

- Reducing carbon emissions in the transportation of tubs is crucial for mitigating climate change and promoting sustainable practices. We have a service department both in Norway and Iceland that optimizes the transportation of the tubs.

- We have calculated our Corporate Carbon Footprint and Product Carbon Footprint for scope 1 and 2 and some levels of scope 3. To offset our emissions, we have invested in carbon credit from Nicaforest, a Gold Standard-certified member. Nicaforest is a high-impact reforestation project that fosters a positive impact beyond mitigating emissions. Nicaforest holds an FSC (Forest Stewardship Council) certification.