Choosing the right type of fishing tubs for commercial fishing operations is an important decision that can impact the efficiency, safety, and overall success of the business. There are several reasons why commercial fishing companies might opt for iTUB fishing tubs.

Strength: Our tubs are triple-layered and made of one material throughout (outer shell and the insulation), making this the strongest in the market. The tubs are made from food-grade polyethylene (PE) and are designed to withstand impact and rough handling, reducing the risk of physical damage to the fish. Ensuring that the fish remains intact is crucial for maintaining quality.

Insulation: The primary advantage of the PE-insulated fishing tubs is the ability to maintain a consistent temperature. The insulation helps to keep the fish cold and minimizes temperature fluctuations, which is crucial for preserving the freshness and quality of the seafood. This reduces waste and helps maximize the value of the fish. By maintaining a low temperature, our PE-insulated tubs extend the shelf life of the seafood. This is particularly important when the fish need to be transported over long distances before processing. Fish stored in quality PE tubs is less likely to experience textural changes or develop off-flavors due to temperature variations. This results in higher-quality seafood products.

Hygiene: We work hard to secure our customers with clean tubs. As of today, we have washing facilities in Grimsby in the UK, Boulogne Sur Mer in France, Urk in the Netherlands, Hanstholm in Denmark, and Bremerhaven in Germany. At the washing stations, the tubs are washed with hot water and food-approved soap to remove oily articles. Then the tubs are sprayed with a special disinfectant that removes bacteria. The Closed Core Cell design of the tub means that no liquid is absorbed within the insulation of the tub. This one-piece seamless design improves overall hygiene. They have a smooth surface (non-porous) which is easy to clean and drain. Proper hygiene is essential for preventing contamination and maintaining product quality.

Durability: Overall, PE fishing tubs are chosen for their durability and suitability for the demanding conditions of the fishing industry. Polyethylene (PE) is a strong and robust plastic material. It can withstand impacts, rough handling, and environmental stressors without breaking or cracking easily. This makes PE fishing tubs resilient to the physical demands of fishing operations. PE is a durable material that can withstand harsh marine environments, including temperature tolerance, impact, chemical, UV, and corrosion resistance. This durability ensures that the tubs can endure the rigors of commercial fishing operations for up to 12-15 years. On average, we repair about 20% of all tubs every year. This prolongs the durability of the tubs which then improves the quality and safety of our stock.

Stackability: The tubs are designed to stack efficiently, which optimizes space in storage and transportation. The tubs are equipped with strong, dependable hoisting grips have easy access on two sides for pallet jacks, and have forklift access on all four sides. This makes our tubs safe during handling and transport.

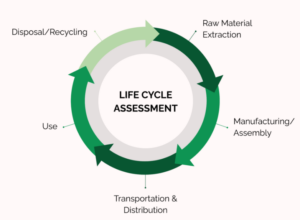

Sustainability: Since the inception of iTUB, we have taken action to reach full circularity. Our tubs are designed to be 100% recyclable. They are produced with geothermal energy and repaired to lengthen the longevity of the tubs. The tubs are reused and shared in a pool system which reduces the need for natural resources. In fact, reuse and repair are the building blocks of the circular economy. This can contribute to climate change mitigation by preventing resource depletion, diverting products and materials from landfills. By incorporating circular economy into our product design, manufacturing, and end-of-life management, we extend the life cycle of our products. Adopting a circular economy approach has allowed us to rely less on virgin fossil fuel-based resources to produce the tubs. New tubs are made with 30% recycled plastic material. In addition, the circular economy has fostered creative thinking and innovation. To become a net-zero emission company, we have calculated our Corporate Carbon Footprint and Product Carbon Footprint for Scopes 1 and 2 and some levels of Scopes 3. To offset our emissions, we have invested in carbon credit from NICAFOREST, a Gold Standard-certified member. Nicaforest is a high-impact reforestation project that fosters a positive impact beyond mitigating emissions and holds an FSC (Forest Stewardship Council) certification.

Pooling: In today’s fast-paced business environment, flexibility is key. Pooling tubs provide businesses with a large network of high-quality PE tubs that can meet the varying needs and demands of different customers, markets, and seasons. This provides our clients with the agility to adapt to changing market conditions and customer demands. We ensure that the tubs are delivered and collected at the right time and place, reducing the risk of shortages or delays. Pooling tubs maximize the utilization of natural resources reduce the need for individual ownership and extend tubs life cycle through increased usage. This contributes to a more sustainable supply chain, as the tubs are shared and reused within a circular economy model. This reduces waste and carbon footprint by using fewer natural resources and energy. Pooling and renting also support social responsibility initiatives by complying with environmental standards and regulations. At iTUB, our tubs do not end up in landfills. All tubs are recycled once they are deemed unusable.

Safety: During the time the tubs are in service, they are repaired and inspected regularly by qualified inspectors. These tests are performed to uphold our safety and quality standards. We randomly inspect older tubs for stacking stability, hoisting strength, dimensions, wounds, patches, and overall appearance. The tests are performed in Saeplast’s specially-made facility in Dalvik Iceland where it is possible to test the hoisting and staking strength of the tubs. These two factors are critical when it comes to testing the strength and durability of the tubs. To us, safety is fundamental and non-negotiable.

Traceability: Our tubs come with ready-to-use RFID (Radio Frequency Identification) tags for traceability. This allows our clients to have real-time inventory accuracy across all their stages, it drives savings, efficiency, and profitability. Also, traceability establishes trust and transparency by providing certified sustainability credentials with data. This also reduces waste and creates direct communication channels which are beneficial across all stages of the supply chain.

Our tubs provide an effective means of preserving the quality and freshness of fish and seafood during storage and transportation. Their insulation properties, durability, and versatility make them a practical choice for a wide range of fishing applications.